Welcome to the ultimate guide for your new Miller Bobcat 250 Parts Manual, designed to ensure a smooth and efficient experience. This comprehensive manual provides detailed information on parts identification, maintenance, and repair procedures, helping you maximize the performance and longevity of your welding generator. With clear diagrams and descriptions, it serves as an essential resource for both professionals and DIY enthusiasts, ensuring proper upkeep and troubleshooting of your equipment.

1.1 Overview of the Miller Bobcat 250 Welding Generator

The Miller Bobcat 250 is a robust, engine-driven welding generator designed for versatility and reliability. It supports MIG, TIG, and Stick welding processes, making it ideal for professionals and fieldwork. Known for its portability and durability, the Bobcat 250 delivers consistent power for demanding tasks. The optional EFI model enhances performance with higher power output and improved fuel efficiency, ensuring superior welding results across various applications.

1.2 Importance of the Parts Manual for Maintenance and Repair

The Miller Bobcat 250 Parts Manual is crucial for maintaining and repairing your welding generator. It provides detailed diagrams, part numbers, and repair procedures, ensuring proper identification and replacement of components. Regular maintenance, as outlined in the manual, helps prevent equipment downtime and ensures optimal performance. Using genuine Miller parts guarantees reliability and longevity, making the manual an indispensable tool for owners and technicians alike.

Key Components of the Miller Bobcat 250

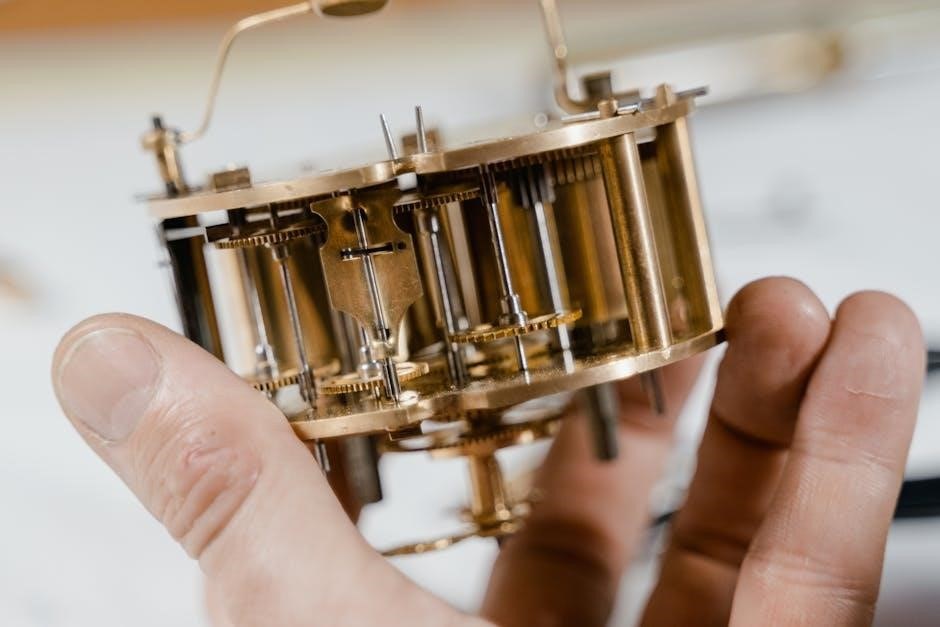

The Miller Bobcat 250 comprises essential components like the robust engine, powertrain, welding system, and electrical parts. These elements work together to deliver reliable welding and power generation.

2.1 Engine and Powertrain Components

The Miller Bobcat 250 features a powerful diesel engine, delivering robust performance for welding and power generation. Key components include the fuel injection system, cooling system, and alternator. The engine’s design ensures durability and efficiency, with a focus on consistent power output. Regular maintenance of these parts, as outlined in the manual, is crucial for optimal performance and longevity of the equipment.

2.2 Welding System and Electrical Components

The Miller Bobcat 250 is equipped with a versatile welding system, offering DC constant voltage for consistent wire welding performance. Electrical components include output terminals, connectors, and control modules. The manual provides detailed diagrams and part numbers for these elements, ensuring accurate identification and replacement. Proper maintenance of these components is essential for reliable operation and high-quality welds, as outlined in the guide.

Maintenance and Service Guidelines

The manual outlines essential maintenance routines, including oil changes, filter replacements, and electrical system checks. Regular servicing ensures optimal performance, prevents breakdowns, and extends equipment lifespan.

3.1 Scheduled Maintenance Procedures

Regular maintenance is crucial for optimal performance. The manual provides detailed schedules for tasks like oil changes, air and fuel filter replacements, and spark plug inspections. It also outlines procedures for checking and maintaining the welding generator’s electrical systems, ensuring reliability and preventing unexpected breakdowns. Following these routines helps extend the lifespan of your Miller Bobcat 250 and maintains its efficiency and safety standards.

3.2 Troubleshooting Common Issues

The manual provides a detailed troubleshooting guide to address common issues like engine startup problems, inconsistent welding output, or electrical system malfunctions. It offers step-by-step solutions, such as checking fuel levels, inspecting spark plugs, or verifying cable connections. Additionally, it covers diagnosing issues related to overheating, low power output, and arc instability, ensuring users can resolve problems efficiently and safely, minimizing downtime and maintaining productivity.

Parts Replacement and Upgrades

This section covers procedures for replacing parts and upgrading your Miller Bobcat 250. Use genuine Miller parts to ensure compatibility and maintain optimal performance. Upgrades can enhance functionality and extend equipment life.

4.1 Identifying Genuine Miller Parts

To ensure authenticity, genuine Miller parts are marked with the Miller logo and part number. Always purchase from authorized dealers to avoid counterfeit products. The parts manual provides detailed descriptions and diagrams to help identify each component accurately. This ensures compatibility and maintains the performance of your Bobcat 250. Proper identification is crucial for warranty coverage and optimal functionality.

4.2 Compatibility with Other Miller Welding Equipment

Much like its sibling, the Miller Bobcat 250 is designed to integrate seamlessly with other Miller welding equipment, such as wire feeders and remote controls. Genuine Miller parts ensure compatibility, maintaining optimal performance across all connected devices. Using authentic components guarantees reliable operation and extends the lifespan of your equipment. Always consult the manual or contact Miller support for confirmation before pairing with other tools.

Safety Precautions and Best Practices

Always wear protective gear, including welding helmets and gloves, to ensure safety. Proper ventilation is crucial to avoid inhaling fumes. Follow manual guidelines for handling electrical components and equipment to prevent accidents and ensure optimal performance. Regularly inspect equipment for damage or wear to maintain safety standards and prevent potential hazards during operation.

5.1 Operating Safety Guidelines

Always stop the engine before performing maintenance or repairs. Ensure proper ventilation to avoid inhaling harmful fumes. Avoid operating in hazardous environments with flammable materials nearby. Keep loose clothing and long hair tied back to prevent entanglement. Use proper grounding techniques to prevent electrical shocks. Never overload the welding generator beyond its rated capacity. Follow all safety warnings and instructions provided in the manual to ensure safe operation and protect yourself from potential risks.

5.2 Storage and Handling of Parts

Store parts in a cool, dry environment, away from direct sunlight and moisture. Use the original packaging or protective materials to prevent damage. Handle components with care to avoid scratches or contamination. Ensure all parts are securely fastened during transport to prevent loss or damage. Refer to the manual for specific storage recommendations for sensitive or specialized components, ensuring their longevity and functionality when needed for repairs or upgrades.

Access to the Miller Bobcat 250 Parts Manual PDF

Download the Miller Bobcat 250 Parts Manual PDF directly from Miller’s official website or authorized distributors. This resource is freely available for easy access and reference.

6.1 Downloading the Manual from Authorized Sources

To download the Miller Bobcat 250 Parts Manual PDF, visit Miller’s official website at MillerWelds.com or authorized dealers like Weldfabulous and Amazon. Navigate to the support section, enter your model number, and access the PDF. Ensure you use genuine sources to avoid counterfeit documents and get accurate information for maintenance and repairs. This guarantees reliability and safety for your equipment.

6.2 Navigating the Manual for Specific Parts Information

The Miller Bobcat 250 Parts Manual PDF is structured for easy navigation, featuring a detailed table of contents and index. Use the search function to quickly locate specific parts by name or number. Diagrams and exploded views provide visual guidance, while part numbers and descriptions ensure accuracy. For precise information, refer to sections like the complete parts list and maintenance schedules.

Common Repairs and Parts Replacement

The Miller Bobcat 250 often requires replacement of engine components, welding system parts, and electrical elements. Regular maintenance and genuine Miller parts ensure optimal performance and reliability.

7.1 Frequently Replaced Parts and Their Functions

The Miller Bobcat 250 commonly requires replacement of engine components, such as spark plugs and air filters, to maintain performance. Welding torches and nozzles wear out over time and need regular replacement. Voltage regulators ensure stable power output, while fuel filters prevent engine damage. These parts are essential for optimal functionality and are detailed in the manual for easy identification and replacement.

7.2 DIY Repair Tips for Beginners

Start with simple repairs like replacing air filters or spark plugs, using genuine Miller parts. Always consult the manual for guidance. Ensure the machine is turned off and cool before starting work. Wear protective gear and follow safety guidelines. For complex issues, seek online tutorials or forums for support. Keep a well-organized toolkit and label parts for easy reassembly to avoid mistakes during DIY fixes.

Warranty and Support Information

The Miller Bobcat 250 is backed by a comprehensive warranty covering parts and labor. For inquiries, contact Miller’s customer support team for assistance and genuine parts.

8.1 Warranty Coverage for Parts and Labor

Maintenance of factory performance requires using genuine parts. Miller Electric offers a comprehensive warranty covering parts and labor for the Bobcat 250. Contact Miller’s customer support for details. Service parts ensure original performance, and the warranty provides coverage for repairs and replacements. Genuine parts are essential for maintaining equipment efficiency and extending its lifespan. Always verify warranty terms for specific coverage details.

8.2 Contacting Miller Customer Support

For assistance with parts or repairs, contact Miller Electric Mfg. Co. at 1635 West Spencer Street, Appleton, WI; Visit their official website or call for support. Genuine parts ensure warranty coverage and optimal performance. Miller’s customer service team is available to address inquiries and provide solutions for your Bobcat 250 needs, ensuring your equipment operates at its best with authentic components.

Compatibility with Accessories and Upgrades

The Miller Bobcat 250 supports various accessories and upgrades, such as welder generators and powertrain components, ensuring enhanced performance. Use genuine parts for compatibility and warranty compliance.

9.1 Recommended Accessories for Enhanced Performance

For optimal performance, consider adding genuine Miller accessories like remote controls, wire feeders, and protective covers. These enhance functionality and durability, ensuring your Bobcat 250 operates at peak efficiency. Always consult the parts manual or contact Miller support for compatibility verification to maintain warranty coverage and performance integrity.

9.2 Upgrading Your Bobcat 250 for Improved Functionality

Upgrading your Miller Bobcat 250 can significantly enhance its performance and functionality. Consider adding advanced control panels, upgraded cooling systems, or digital interfaces for better monitoring and control. Always refer to the parts manual PDF for compatible options and follow installation guidelines to ensure optimal results. Using genuine Miller parts guarantees compatibility and maintains your warranty.

Environmental and Storage Considerations

Proper storage and environmental care are crucial for maintaining your Miller Bobcat 250. Store it in a clean, dry space, avoiding extreme temperatures and humidity. Follow eco-friendly disposal practices for old parts to minimize environmental impact. Always refer to the manual for specific storage and handling guidelines to ensure longevity.

10.1 Proper Storage Conditions for the Welder and Parts

Store the Miller Bobcat 250 in a clean, dry, well-ventilated area, away from direct sunlight and moisture. Avoid extreme temperatures (below -20°F or above 120°F) and humidity levels. Ensure the unit is placed on a stable, level surface to prevent damage. Cover the welder when not in use to protect it from dust and contaminants. Always follow the manual’s specific storage guidelines for optimal preservation and functionality.

10.2 Disposal of Old or Damaged Parts

Dispose of old or damaged Miller Bobcat 250 parts responsibly, adhering to local environmental regulations. Recycle metal components and properly discard hazardous materials like batteries or fuels. Use authorized service centers for safe disposal to prevent ecological harm. Ensure all flammable liquids are drained and parts are cleaned before disposal to comply with safety standards and minimize environmental impact.

The Miller Bobcat 250 Parts Manual is an invaluable resource for maintaining and repairing your welding generator. By following its guidelines, you ensure safety, efficiency, and longevity. Regular use of this manual will help you maximize the potential of your equipment and keep it in optimal working condition for years to come.

11.1 Summary of Key Takeaways

The Miller Bobcat 250 Parts Manual is a vital resource for owners, providing detailed parts identification, maintenance schedules, and repair guidelines. It ensures optimal performance, safety, and longevity of your equipment. By following the manual, users can troubleshoot issues effectively, replace parts correctly, and maintain their welding generator in prime condition. Regular reference to this guide is essential for maximizing functionality and preventing unnecessary downtime.

11.2 Encouragement for Proper Maintenance and Use

Proper maintenance is crucial for the longevity and safety of your Miller Bobcat 250. Regularly refer to the parts manual for scheduled maintenance procedures; Replace worn-out parts with genuine Miller components to ensure optimal performance. Adhering to these guidelines will not only extend the life of your equipment but also enhance its efficiency. Consistent upkeep ensures your welding generator operates safely and effectively every time.